Discover our full offer

Artego Machining technology Artur Kalbarczyk is a company that has been providing the highest quality services in the field of metal processing for years. Our offer includes a wide range of services such as CNC turning, CNC milling, grinding, CNC drilling, electroplating, waterjet cutting and plasma cutting. Thanks to our modern machinery and experienced staff, we are able to cope with the most demanding projects. Check out our offer below!

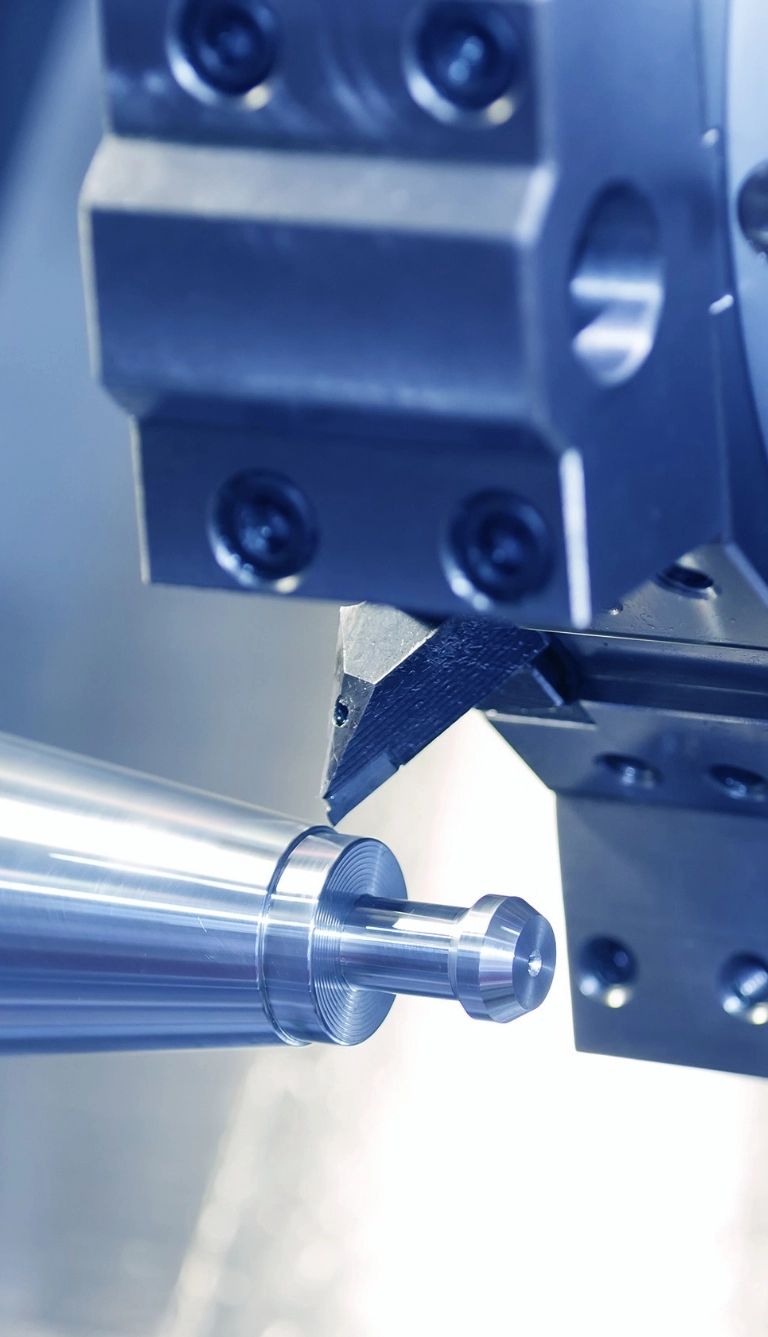

CNC TURNING

ø500 mm – długość 1000 mm

During CNC turning, the workpiece is not stationary. It performs a rotational movement while the cutting tool moves in a straight line. Our company uses this method to enable turning of all types of metal parts. Thanks to high automation, the processed items are characterized by precision of workmanship and the necessary repeatability of parameters.

CNC MILLING

1000 x 500 x 700 mm

CNC milling is one of the machining methods that involves machining a stationary object while the milling tool rotates. The rotating blades of the tool shear the top layer of the part until the desired effect is achieved. Milling ensures high precision, making it a very popular method in our production plant.

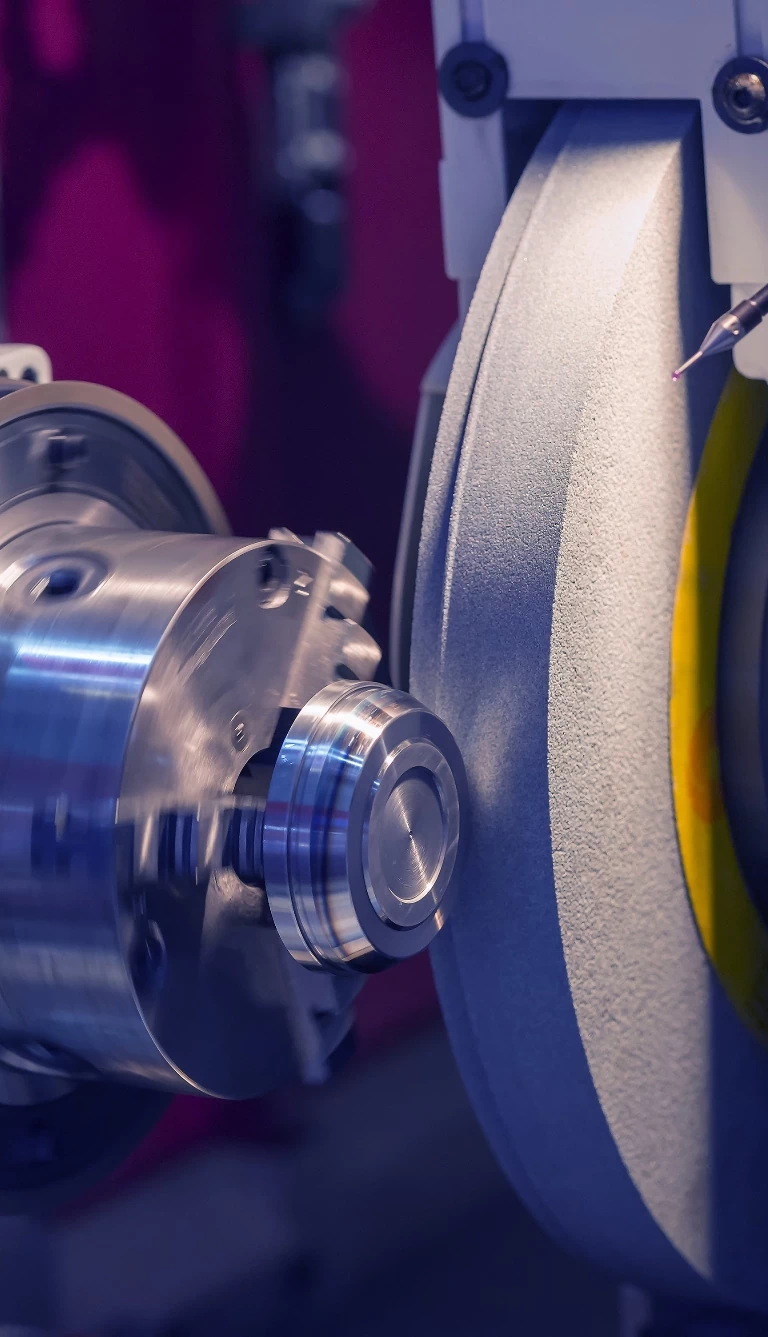

GRINDING

Cutting metal materials usually leaves a rough surface and uneven edges. Materials left in such a condition may damage the machine by falling metal fragments into delicate systems. Therefore, all machining of holes, shafts or surfaces should be completed with grinding. This is an extremely precise finish that aims to give perfect smoothness and protect the processed material.

CNC DRILLING

CNC drilling is used in the aviation sector, as well as in the gas and oil industries. We work with materials such as steel, brass and aluminum. We process materials with both typical and non-standard parameters.

GALVANIC PROCESSING (COOPERATION)

We also deal with galvanic treatment used to cover the surface of the material with a thin layer of metal with properties and parameters other than the metal from which the object is made, most often to protect and protect elements made of steel or cast iron against corrosion.

WATER JET CUTTING

1400 x 2540 mm

Waterjet cutting is a cold process that easily competes with thermal methods of separating materials. The biggest advantages of water cutting are the good quality of the cut surfaces and the lack of deformations - the temperature during the process does not exceed 100°C. We use a stream of water with a pressure of 4,000 bar passed through a nozzle with a very small diameter.

PLASMA CUTTING

1500 x 3000 mm

Plasma cutting is currently the most popular thermal cutting process. Plasma cutting is often used to cut materials up to approx. 30 mm thick.